Electronic scrap – a challenge with potential

The throw-away industry of consumer society

When someone buys a new smartphone (about every 1.5 years statistically,) they generally don't give much thought to their old device. Yet the waste stream created by electronic devices (also known as WEEE or “waste electronic and electrical equipment”) is really astonishing – the world’s biggest waste stream of the future. But the “end-of-life” stage for these electronics could still be quite long and eventful. Meet Susi – my personal assistant, my organizer, my source of unlimited knowledge and my link to the outside world. Susi is my two-year-old smartphone. Following a tragic and preventable mishap, the poor thing is now permanently out of commission. So, it looks like Susi has to go. Let’s come along and see where she’s headed.

How will Susi get to E-heaven?

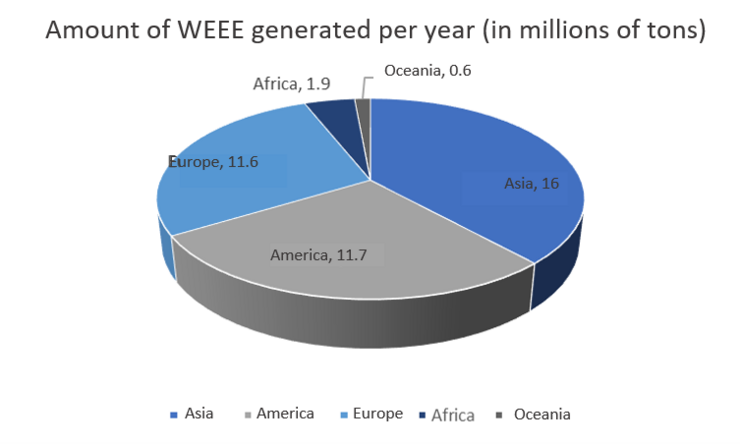

First, waste is collected in central locations. Since I'm an eco-friendly kind of guy, I'm taking Susi to a recycling center. This is the first stop for many retired gadgets. Of course, some electronics don’t take the law-abiding path straight to the recycling yard. Instead, they stop off in the woods first or clandestinely slip away to third-world African countries like Nigeria or Ghana. Monitoring is limited and difficult, so the statistics on E-waste are really just estimates. It’s believed that approximately 42 million tons are produced worldwide, the biggest contributors being the US, China, Latin America and Europe (1). In Europe we produce about 14 – 20 kg per capita annually (2,3). Growth rates are increasing the fastest in growing economies, but the trend can be seen in all countries. Despite various regulations and new tracking methods using RFID and GPS, it’s still practically impossible to get an accurate idea of where all this E-waste is going. Case studies have shown that E-waste travels very slowly in comparison with other types of garbage and makes a lot of stops along the way before reaching its final destination, often just a few hundred kilometers away (2). So, chances are that I’ll never really know where Susi goes and what happens to her.

The first stage of the after-life process for smartphones depends a lot on household recycling practices. These are small electronics, which don’t tend to get brought in for recycling as often as large equipment like refrigerators. For one thing, smartphones are small, so they’re easier to toss in the trash. They’re also typically designed as disposal products, so they don’t last long. What’s more, the use of electronic components has been going up in all product categories (e.g. children’s toys). According to a study in the UK, there’s a lack of awareness with regard to the need for E-waste collection, as well as a lack of knowledge about the infrastructure responsible for it. (3) All this adds up to the fact that a lot of small electronics do not get sent for recycling or reprocessing when they're thrown away. In Western countries, about 10 – 15 % of smartphones get recycled or reprocessed. (4) This number stands in strong contrast to the European WEEE Directive, which mandates a 70 – 80 % rate of recycling for E-waste. (5) The goal of this directive has been to drastically reduce the amount of E-waste in landfills and to salvage the raw materials it contains. Before it was enacted for example, electronics in the UK were being dumped in landfills or incinerated at waste-to-energy plants at a rate of up to 90 %. With both incineration and dumping, a number of poisonous and environmentally hazardous materials end up either seeping unfiltered into the ground or escaping into the air through combustion.

Ensuring reusability and recyclability is important to our customers in the “throw-away" industry, especially given the current emphasis on the issue of climate change. That’s how we know that these processes often require more than a standard ERP system. Click here to find out why you should consider an industry solution that is tailored to your needs:

These toxic materials such as lead, arsenic, chromium and mercury are found in WEEE and have already been detected in the environment as well as in people within range of landfill sites. Many developing nations do not have such strict regulations or even any regulations at all on hazardous materials, so the problem simply gets exported. The effects are not felt by the actual consumers or by the producing countries. (6) That’s why we need global solutions to tackle the issue across the board and get smartphone components to recycling facilities.

What parts of Susi can actually be recycled?

A smartphone is made up of a range of different materials, some of which are inseparably connected to one another. This often makes the task of recycling them technically and economically difficult. That’s why most recycling companies focus on salvaging valuable metals. Not only are these easier to separate (they might stick to a magnet or have a higher specific weight,) they also have higher resale values. The main constituents of a smartphone are copper, zinc, tin, nickel, aluminum and lead. Smartphones also contain smaller amounts of very valuable metals like silver, gold and palladium. (2) Which of these materials are actually extracted depends on the available technology, the material composition (e.g. alloying) and the cost-effectiveness. If extraction is more costly and labor-intensive than market prices for these raw materials, it doesn’t make much sense for companies to recycle them. Another point to consider has to be the product design, so that individual raw materials can be removed and recycled at the end of the product life cycle.

Susi gets broken down into parts

So if Susi is beyond repair, or if fixing her isn’t worth the cost, she will likely get broken down into her individual components or at least enough to allow any valuable components like gold or copper to be taken out. This whole process depends on what country Susi ends up in. The electronic scrap trade can be a lucrative business. Because of the strict requirements imposed on disposal companies in some countries, electronic scrap is simply exported – problem solved. Except that the raw materials often go with it (about 50 – 80 %). (4) As a result, in third world countries, we find entire sections of land that are stacked several meters high with electronic waste. As it degrades, toxins seep into the earth or evaporate into the air when the waste is incinerated to recover metals.

The waste management industry is a dynamic market. If you want to succeed in this sector, you have to be able to react quickly. Waste regulations and reporting requirements are getting more and more stringent. Our industry solution cc|environmental services can help you stay on top of it all. Ask our consultants:

Conclusion

The effects are causing great harm to both people and the environment. At the same time, raw materials are getting harder to come by. Exporting our responsibility means giving up the raw materials, too. There seems to be enormous potential for urban mining (7) – systematically collecting and recycling secondary raw materials – but for now, it’s hardly being tapped. Urban mining is based on four pillars: smart design, resource cadasters, urban prospecting and new technologies. The idea is to pursue a circular economy. As with the related concept of landfill mining, it’s about counteracting the exhaustion of raw materials and the destruction of the environment. A lot of ideas are coming out of this field of research and technology. One study, for example, deals with bacteria that could help with the decomposition of smartphones. Hopefully, people will continue to come up with ideas, expand research and take political, social and economic steps towards establishing a circular economy.

- Lee, D.; Offenhuber, D.; Duarte, F.; Biderman, A.; Ratti, C.: Monitour: Tracking global routes of electronic waste. 2018, Waste Management 72, S.362-370.

- De Marco, I.; Caballero, B.M.; Chomón, M.J.; Laresgoiti, M.F.; Torres, A.; Fernández, G.; Arnaiz, S.: Pyrolysis of electrical and electronic wastes. Journal of Analytical and Applied Pyrolysis 82, 2008, S. 179-183.

- Darby, L.; Obara, L.: Household recycling behaviour and attitudes towards the disposal of small electrical and electronic equipment. Resources Conservation & Recycling 44 (200), S. 17-35.

- Tanskanen, P.: Management and recycling of electronic waste. Acta Materialia 61 (2013), S. 1001-1011.

- European Commission: Waste Electrical & Electronic Equipment (WEEE). https://ec.europa.eu/environment//waste/weee/index_en.htm.

- Wang, Z.; Zhang, B.; Guan, D.: Take responsibility for electronic-waste disposal. International cooperation is needed to stop developed nations simply offloading defunct electronics on developing countries. Nature, Vol 536 2016, S. 23-25.

- Wikipedia, https://de.wikipedia.org/wiki/Urban_Mining.