Imagine that you could press a button and view the status of systems or that you could digitally display your products across the entire value creation chain. Let's go one step farther: Imagine you could eliminate failures before they happen. With the capability to map the entire product life cycle, these scenarios are now a reality.

Everything at a glance

Just what do we mean by “end-to-end”? In this context, we mean that products can be digitally mapped out in their entirety from conception to sale to maintenance. So you can keep track of the entire life cycle.

Typically, these kinds of solutions involve complex applications that are cumbersome to work with and rely on a whole bunch of separate systems. Optimum product life cycle management should not require media disruptions. It should be centrally controllable and operable on all devices. In the digital era, we should be able to collaborate on tasks and access important documents anytime and from anywhere.

ERP is the heart of the system topography

A crucial key element to this approach is the ERP system. But it can't meet the aforementioned requirements all on its own. It needs to seamlessly interact with other components. An ERP system is not a stand-alone solution that can be used to perform as many functions and tasks as possible. Rather, the idea is to seamlessly interconnect software and systems in the course of digitalization. Specifically, this means: The individual components (ERP, CRM, data & analytics, modern workplace, etc.) should be combined to form an efficient overall system.

In short:

The transitional path from the classic ERP system to the individual solution platform.

Predictive maintenance

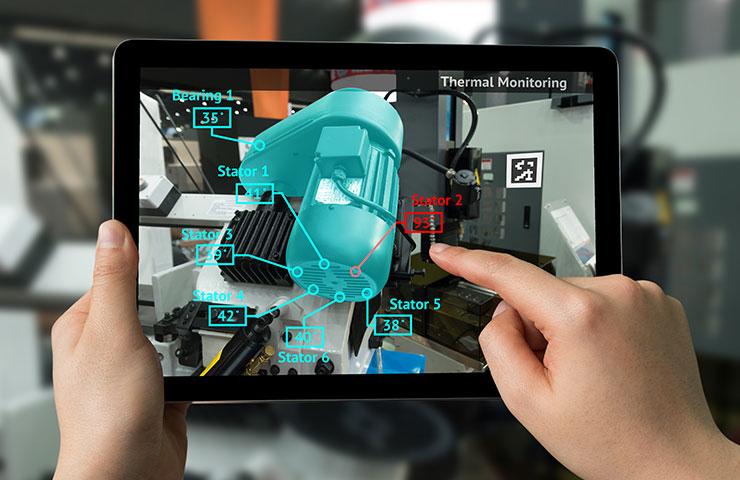

The second key factor for such end-to-end scenarios is predictive maintenance. Malfunctions in machines, equipment and systems can come up at any time and create major expenses due to production downtimes and downstream repairs. But what happens if these malfunctions can be predicted before they happen? What if you could know today which component would fail tomorrow? In predictive maintenance, critical machine components are equipped with sensors that continuously transmit data. Out of this plethora of information, relevant values are selected, formatted as necessary and used to obtain information about the status of a machine. This allows us to predict when critical threshold values will be exceeded, potentially resulting in failure. The information can be prepared as a graphical analysis and displayed on smartphones or tablets. Supervisors are always informed of how a system is operating and are not caught off guard by machine failures. Repairs and machine purchases can be scheduled and implemented well ahead of time.

Services utilizing augmented reality

Predictive maintenance lets you predict when you’ll need maintenance work and time it accordingly. But now there’s also a way to make repairs faster, cheaper and more efficient than ever – augmented reality. When a problem occurs – or rather, when an impending failure is predicted – repairs are performed on site. The maintenance service is connected to the head office, which identifies the failure and issues instructions. This allows businesses to save resources and reduce costs, since the head office can assist multiple service technicians at once and issue instructions to them as they make repairs. Thus, we can guarantee a seamless maintenance cycle – thanks to predictive maintenance and augmented reality.

Summary

Nowadays, a product’s entire value creation chain can be described and represented digitally: from production to intelligent monitoring during installation and down the line to predictive maintenance. Long gone are the days when such end-to-end scenarios sounded like science fiction. Here at COSMO CONSULT, we can help you get there, too, and bring your product life cycle management to the next level!

Keywords

More similar blogposts:

Found what you were looking for?

Start your intelligent search now