QSIL GmbH Quarzschmelze Ilmenau

Glass is a material that has played an important role in Thuringia's industrial economy for centuries. The production of this sensitive material is the basis for high-tech companies like Quarzschmelze Ilmenau - or QSIL for short. The company has perfected the use of quartz glass and reached a level at which only a handful of other companies in the world can compete. To achieve this quality, all elements of the production process must be perfectly coordinated.

In 2006, QSIL saw that the IT structure of the company no longer met its high standards for quality. The search for a new system led the company's leadership to Microsoft Dynamics NAV and the industry and add-on solutions of COSMO CONSULT GmbH that are based on that technology - a combination that met all their requirements.

Many islands, but no land in sight

Outdated IT structures and a heterogeneous software environment were no longer able meet the company's needs. Not only had the company grown continuously over the years, but its IT installations had also been continually adapted and expanded.

IT professionals had to invest more and more time in interfaces for and system maintenance of many isolated solutions. In retrospect, Oliver Kaplan, Head of IT at QSIL AG, described the situation this way: "On a daily basis we felt the consequences of having to maintain the IT structures we had built up over time. In particular, the redundant data collection was repeatedly a source of errors. On top of this the system lacked analytic and forecasting capabilities." "The board needs figures that are updated daily in order to be able to respond to global market developments"; added Martin Weber-Liel, production manager.

Microsoft Dynamics NAV - a good standard

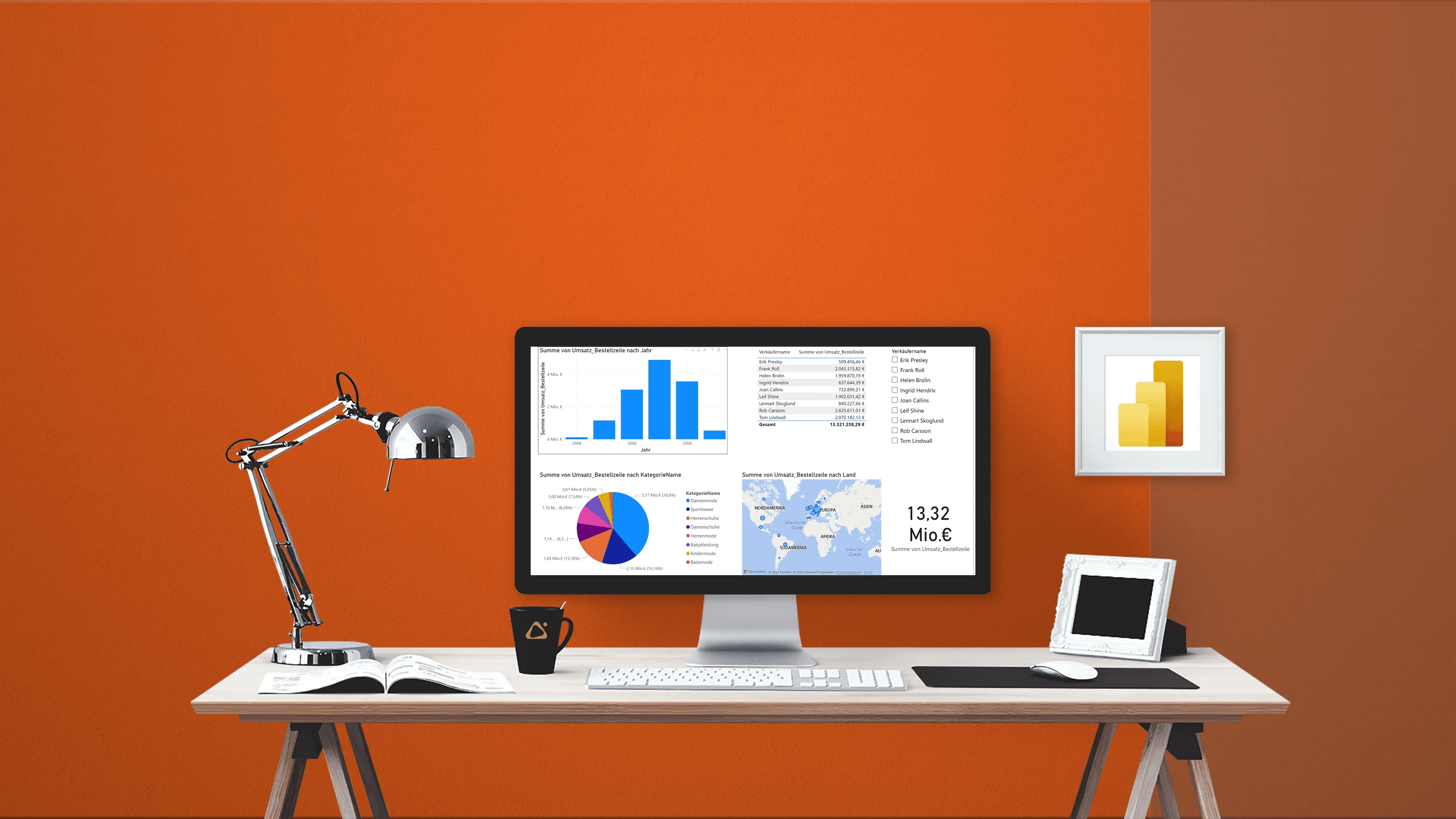

Before choosing the new system, an analysis of the requirements to be met was carried out across all departments. The most important thing was the desire for an integrated IT approach with a central database. All information needed to be recorded and transmitted within the system. They therefore wanted to systematically implement workflow technologies. Business intelligence capabilities were also on the request list. The new system needed to provide extensive analysis options.

Due to positive experiences at board level, Microsoft Dynamics NAV was chosen as the ERP system. Then it was a matter of finding the right partner.

The criteria for the selection process consisted of implementing an integrated solution, using NAV as the ERP system and staying as close to the standard as possible. Several NAV vendors were shortlisted, and three were invited come to the company to make presentations. Finally, QSIL chose COSMO CONSULT as a partner for more than just one reason. "In COSMO process manufacturing we have found a solution whose functions are exactly tailored to our industry," said Oliver Kaplan. "Apart from the software aspect, the ERP experts of COSMO CONSULT also impressed us with their expertise and how systematically they planned and implemented the project".

QSIL now works with other COSMO CONSULT solutions: in addition to process manufacturing, this includes workflow, quality management, supplier evaluation, maintenance and personnel management - all in an integrated ERP solution. Even the sales location in the USA was easily connected to the system. "What particularly impresses me is the operational flexibility of NAV" said Oliver Kaplan.

Oliver Kaplan is sure that NAV and COSMO CONSULT were the right solution: "We have been working with the new system since 2007. Also in day to day use, its performance has been convincing in all the aspects that are important to us. A consistent database, an intuitive user interface, extensive analysis tools - we have an IT system that allows us to focus on our real task: producing the best possible quality of quartz glass. And we can now do that even more efficiently."

More COSMO References

Be part of our COSMOs

Expand your COSMOs and register in our customer portal for exclusive benefits & services

#myCOSMO

Found what you were looking for?

Start your intelligent search now