Machinery

Machinery manufacturing involves complex assemblies and long product lifecycles. Our solution supports order-specific BOMs, engineering integration, and precise cost calculation. Manufacturers benefit from streamlined planning, subcontracting, and project management, while vendor rating and service management ensure strong collaboration. Graphical planning and text modules keep operations aligned, with full control from design to delivery.

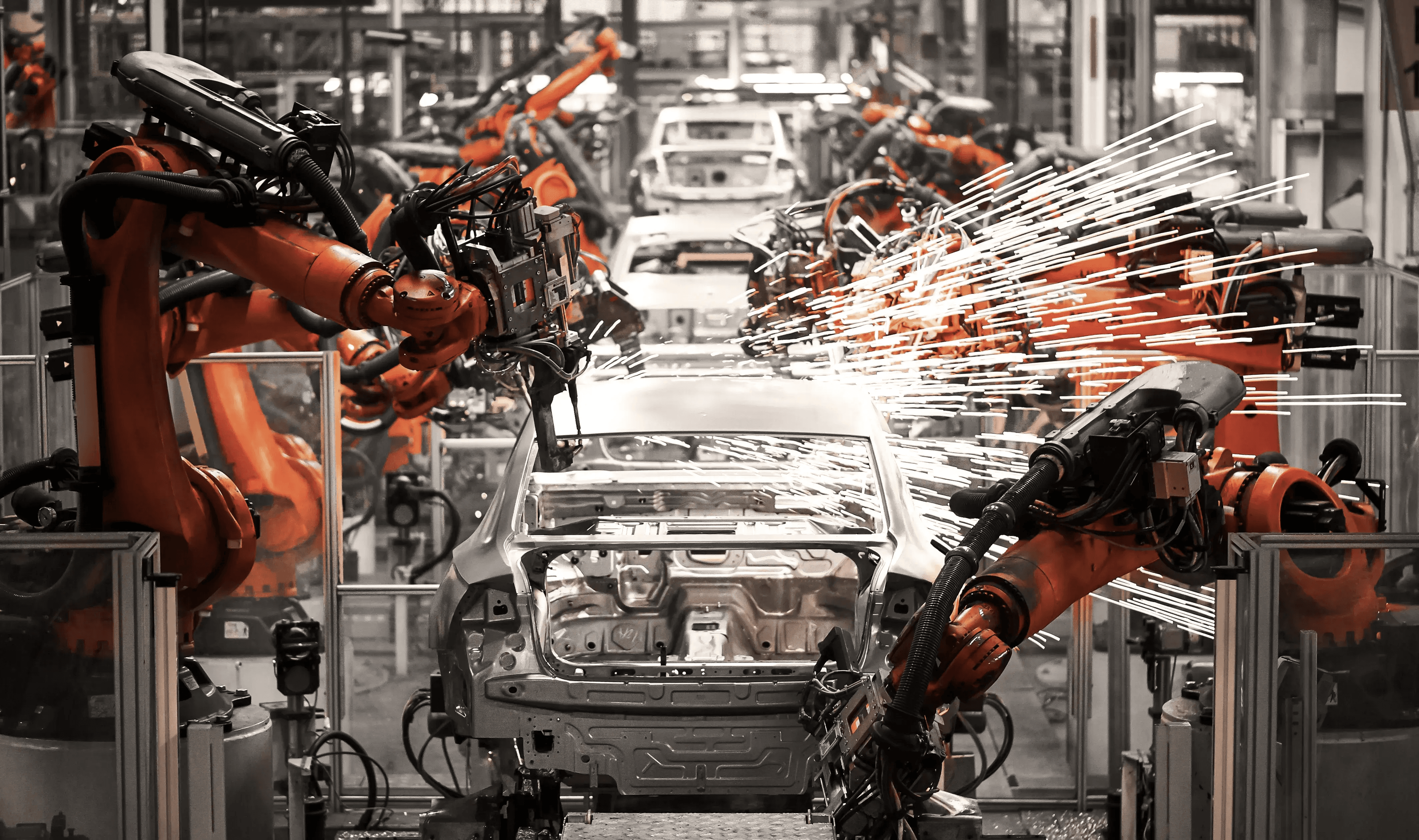

Body, Chassis & Trailers

Automotive and trailer manufacturing involves high variability and complex configurations. Our solution supports accurate quoting, advanced product rules, and sales-order-specific BOMs. With integrated text and graphical planning tools, manufacturers streamline engineering, reduce quoting time, and maintain full traceability. Quality control, vendor ratings, and seamless subcontracting ensure consistent delivery and compliance at every stage.

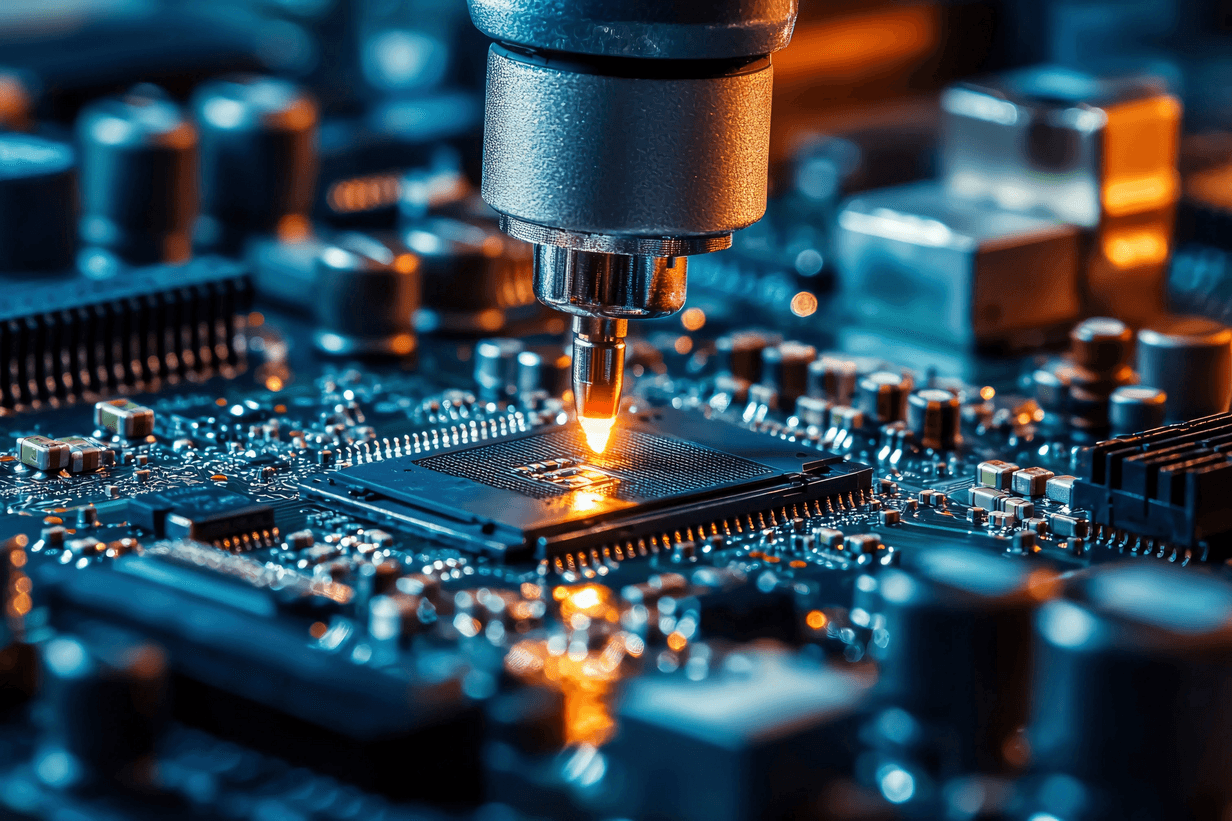

Electronic Devices

Electronics manufacturing demands fast change management and full traceability. Our solution enables precise cost control, efficient quoting, and dynamic configuration of electronic variants. With versioned BOMs, centralized text management, and seamless engineering integration, manufacturers accelerate time to market while ensuring compliance, documentation accuracy, and product quality across global production sites.

Partner Enablement Services

(Pre-) Sales Support Services

Expert demos and support including sales enablement materials..

Implementation Support Services

Deliver faster with proven templates and enablement services.

Partnering with COSMO

The benefits of partnering with COSMO Partner Solutions

COSMO Partner Solutions

#thepowerofpartners

Still have questions?

No worries. We are here to set your mind at ease and answer any questions you may have. Get in touch with our representatives and they will be happy to address any questions or concerns you may have.